Despite the widespread impacts of COVID-19 for all consortium partners, the consortium continues to work together. Remote working has been the answer to prepare for the final demonstration of the PRO-ACT concept – two robots working together in collaboration, a milestone for future exploration of our moon and other objects in our solar system.

The complex and continually evolving situation of the pandemic and restrictions all over Europe have made it very challenging to organize an on-site test at DFKI, similar to the one that the PRO-ACT consortium held in September 2020 for the Phase 1 Tests. Despite this, testing and final demonstration are critical to the project. A way forward had to be found.

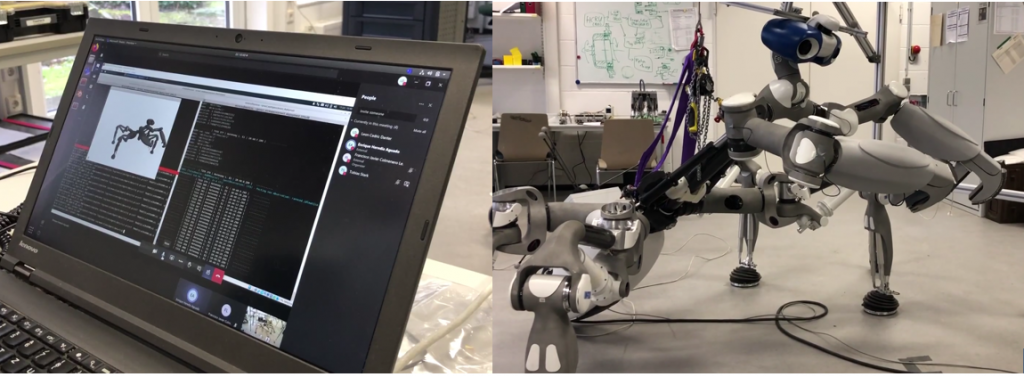

The solution? Remotely working together. All partners quickly adapted their work plans to perform tests together remotely, deploying and testing their software on PRO-ACT robots from their respective remote locations. These challenges are similar to what astronauts in orbit around the Moon or operators on the ground will face while operating robots on the lunar surface.

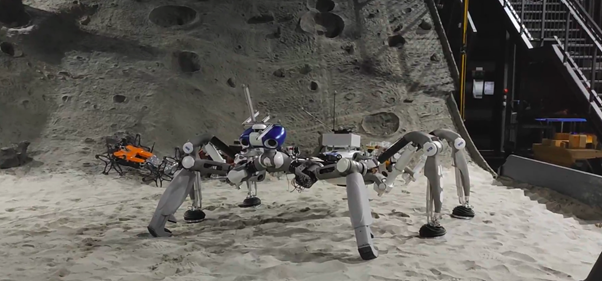

The Mantis robot from the German Research Centre for Artificial Intelligence (DFKI) was remotely controlled by GMV and Space Applications Services to plan and execute a desired motion in the newly developed regolith testbed in the Lunar Hall at DFKI, as shown in the image below. The consortium were able to remotely move the robot in this environment.

The controller for the Mantis arm was also tested, together with the software developed by GMV. This is significant for future exploration as grasping and carrying motions are critical for the exploitation of insitu resources.

Similar tests as Mantis were also performed on the Veles robot, provided by the Industrial Research Institute for Automation and Measurements (PIAP-Space). Additional partners from University City London and LAAS-CNRS worked on aspects related to task planning and control of the manipulators using force sensing.

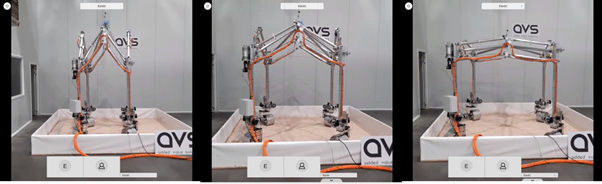

Moving two robots across Europe to be in the same environment was not possible this month, so AVS were able to automate the deployment operation of the Gantry they developed. This function was also controlled remotely using software developed by Space Applications Services. You can see the deployment in steps shown in the images below.

The combination of clever thinking and innovative approaches has kept the project going despite the restrictions on in-person collaboration. The project is preparing for all contingencies in the coming month before the project end-date. There have to be work-arounds if we all need to stay in a strict lockdown. The partners remain optimistic, but cautious as they pursue their goals with the safety of all as the primary requirement.